Wipers : the solution to protect your industrial equipments

Chromex benefits from a wide range or wipers which are mainly mounted in hydraulic cylinders. Wipers are only used for linear applications. We can provide you with different types of wipers according to the mounting conditions: you can’t use the same profiles of wipers for open grooves and for semi-open grooves.

What is the function of wipers ?

Wipers are mainly used in hydraulic cylinders in order to prevent contamination from external elements such as dust, dirt or pollution. In order to prevent the hydraulic cylinders from being contaminated, wipers are mounted on the external side of the cylinder head.

Wipers have another function: they make sure that a thin layer of lubricant stays within the hydraulic cylinder when the piston shaft is retracting. In order to avoid moisture in the hydraulic cylinder, it is also important to check the outside sealing of the wiper within its groove.

Wipers are the only way to prevent the hydraulic cylinder from being contaminated by external factors: they protect the rod and piston seals which will ensure sealing.

The different types of wipers

Chromex benefits from various wipers that can suit different applications within the hydraulic area.

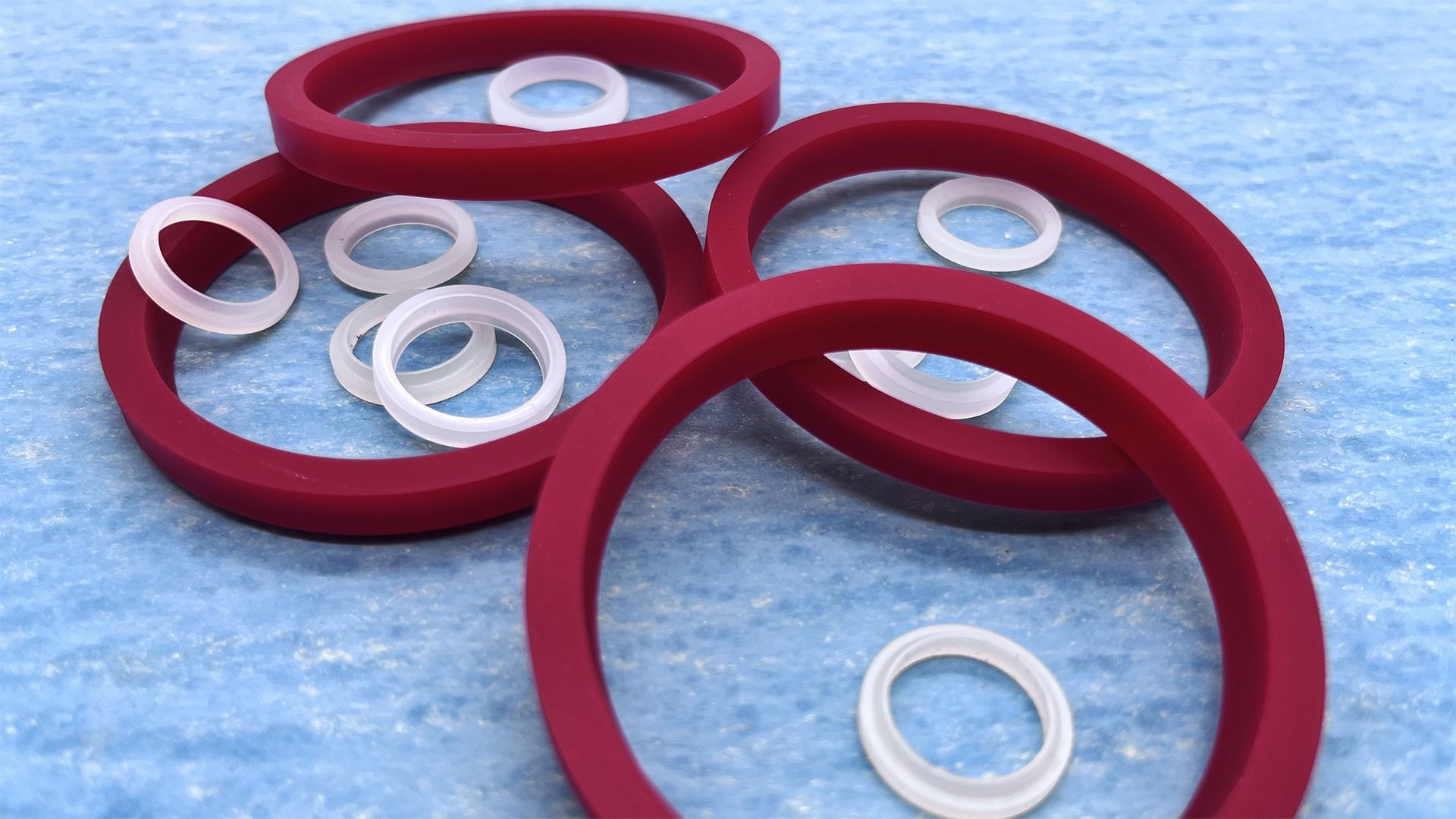

There are two types of assembly which are mainly used in the hydraulic field. Therefore Chromex created a wide range of standardized wipers: soft wipers for semi-open groove and armed wipers for open grooves.

Chromex’ wipers are mainly made Polyurethane (PU), Nitrile (NBR) and of Fluorocarbon (FKM).

Below you will find the specific features of soft and metal case wipers.

Soft wipers

Soft wipers are hydraulic seals which are mounted in closed or semi-open grooves. The flexibility of the rubber (NBR, FKM or PU Rubber) allows a distortion of the seal in order to mount it : soft wipers are mounted at the head of cylinders in order to avoid dirt in the hydraulic cylinder. Rubber wipers can be of simple effect or of double effect: double effect wipers avoid oil or lubricant to leak.

Chromex also benefits from a wide range of double lips wipers : these wipers have a scraping double lip and are easily mounted in semi-open grooves.

Some of our soft wipers can be used in pneumatic cylinders.

Metal case wipers

Armed wipers (also called wipers with metal case) are the one that are used in open grooves. The hardness of the metal case prevents any distortion of the seal, that is why it has to be easily mounted in an open groove. It is important to uniformly push the wiper within its groove in order to ensure optimal use by press-fitting assembly.

Wipers with metal case are simple effect wipers with a reinforced lip. These wipers are only used in hydraulic cylinders.

Chromex benefits from a wide range of wipers with metal case which are coated against corrosion in order to ensure optimal performance over time.