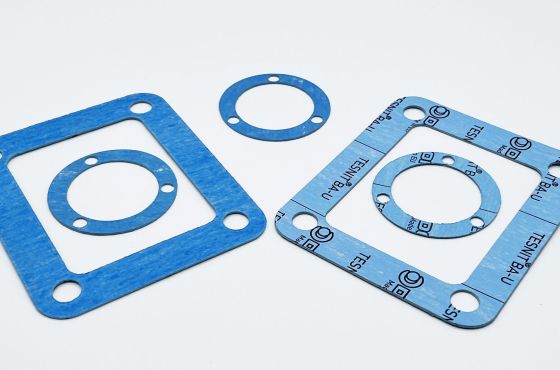

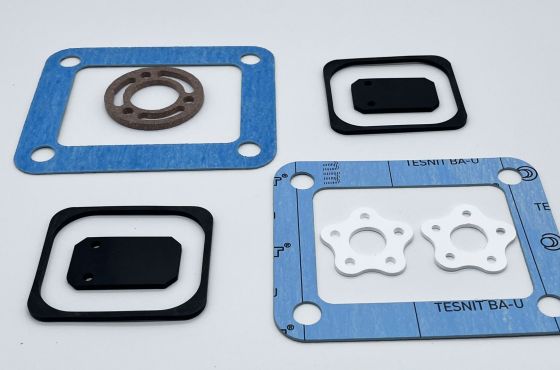

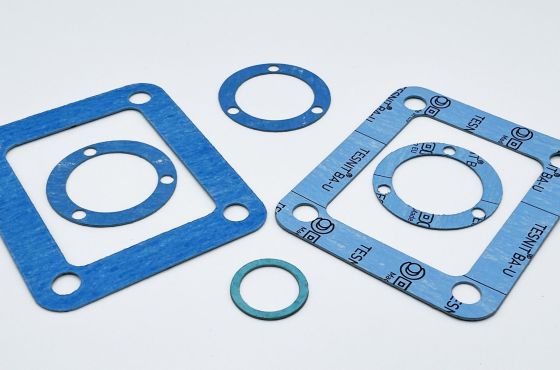

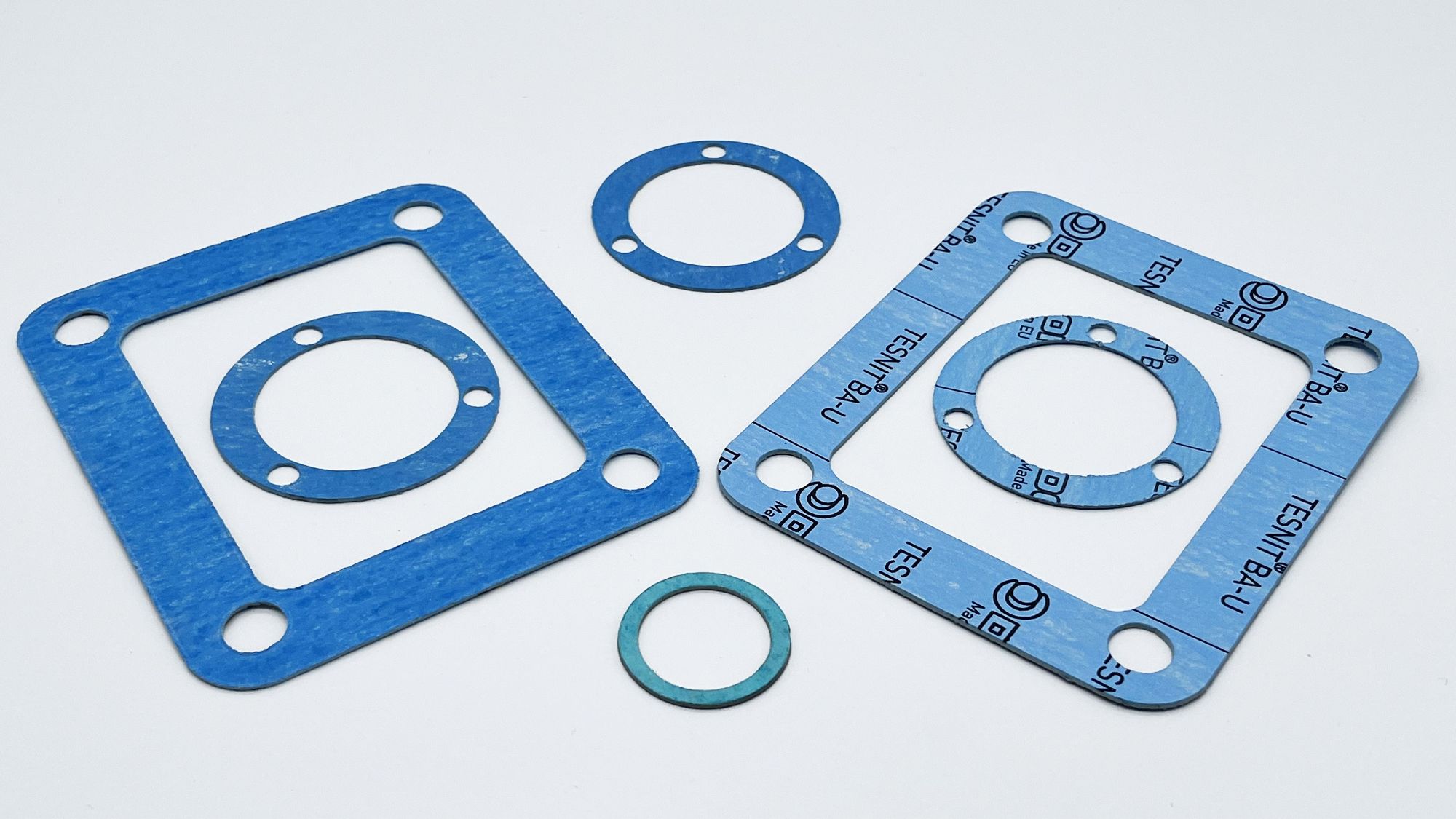

Tailor-made gaskets to ensure perfect sealing

At Chromex, we are able to offer you a wide range of tailor-made seals. We have three different types of manufacturing processes concerning these specific seals : moulded parts, machined parts and cut parts.

Thanks to our French production facility based in Etréchy (near Paris), Chromex is the specialist of cut gaskets within TECHNE group.

Chromex’s Know-How

Production made in France on our site of Etrechy (91)

Thickness possibililty from 0.1 mm to 15mm

Quality control made by our technician after each production

Specific packing of your items

Chromex has manufactured specific flat gaskets for more than 30 years in France. We are able to answer your needs of cut seals whether for sampling or for large series.

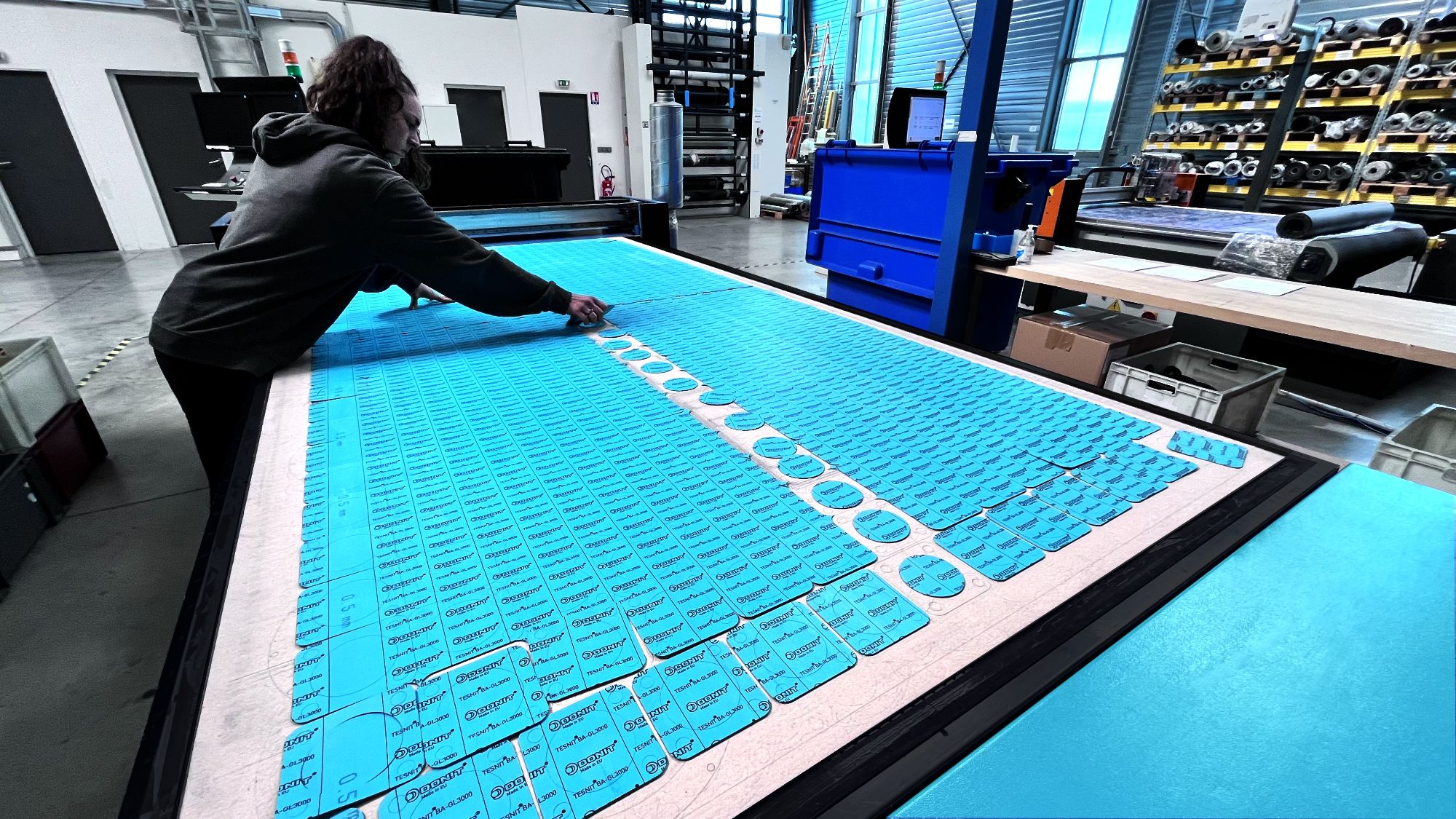

Chromex benefits from a well-established experience in the field of flat seals, namely by mastering 3 different manufacturing processes: blade cutting, waterjet cutting and stamped cutting. We are able to produce your tailor-made gaskets according to the most adapted manufacturing process.

Our cutting machines

Chromex has been working for many years with the Atom® brand concerning its cutting systems, as machine tools. Our cutting machines have the capacity to deal with rubbers, plastics and fibres with thicknesses from 0.1mm up to 15 mm according to the chosen material.

We own several cutting tables in order to answer your enquiries without delay and to offer you French tailor-made cut gaskets. For example, we own CNC (Computer Numerical Control) machines which can be either static or equipped with a conveyor according to the required material.

Thanks to these specific machines, we are able to adapt and produce your flat seals without delay (existing sizes: plates or rolls of rubbers).

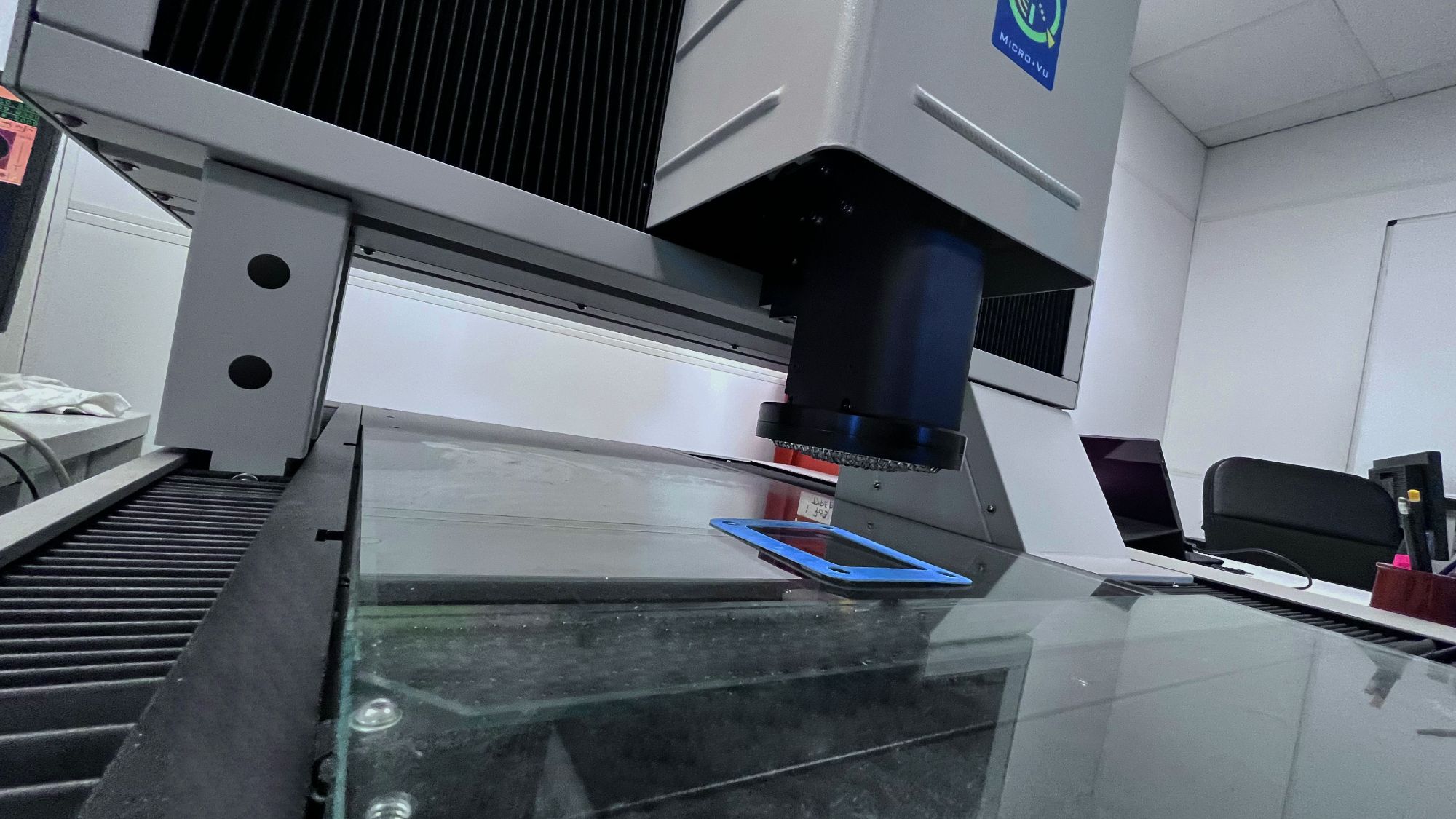

Chromex’s quality testing

Our 30-years-expertise in manufacturing flat seals, allowed us to develop a single Know-How and to meet your requirements. Each seal production is inspected and we can provide inspection reports or compliance certificates on demand. Our production department is equipped with a three-dimensional tool allowing accurate measurements to ensure the best possible quality for our cut gaskets.

Chromex owns also an automatic digital hardness tester to allow measurements in Shore A and in IRHD.

Tailor-made gaskets for small or large series

We have the possibility to produce a wide range of flat seals in different materials: elastomers (NBR, FPM, EPDM, CR, MVQ, SBR etc.), plastics (PTFE, PVC etc.), fibres (Tesnit® BA-U, BA-GL3000, BA-CF, vulcanfibre etc.). Thanks to several of our assets (single know-how, skilled staff, modern and efficient machines) we are able to manufacture seals according to your needs and requirements: from prototyping to large series or from sampling to pre-production models.

Our sales representatives will help you determine the production process that will be the most economic and offer the best quality according to your requirement specifications.

Every year, Chromex manufactures more than 5.000 different tailor-made seals references in various quantities, ranging from one piece to several hundred thousand pieces.