Fibre gaskets : a reliable sealing solution

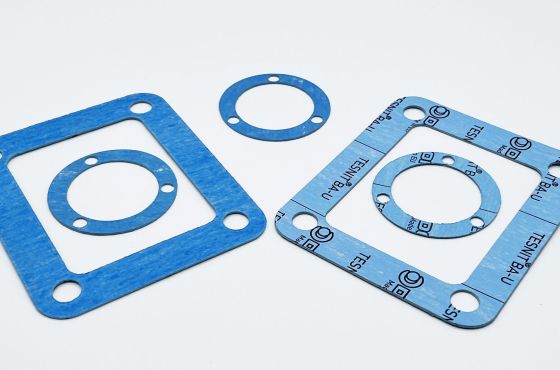

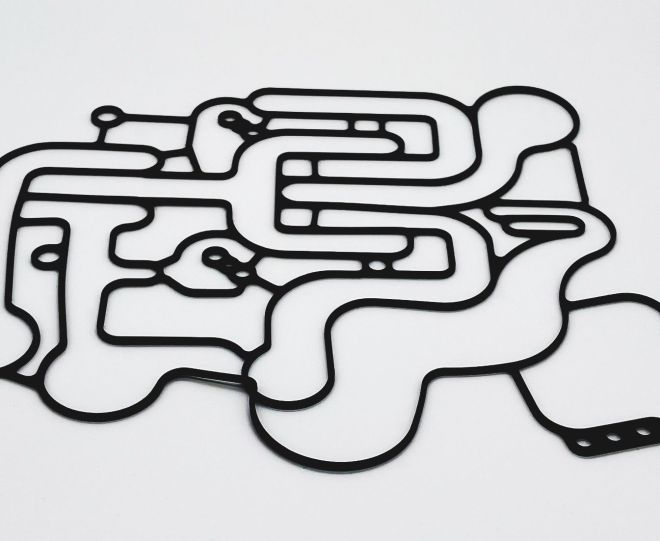

Our expertise as a cut gaskets producer enables us to offer you a wide range of tailor-made gaskets in various fibres. These gaskets can be used for various applications in the industrial sealing area, such as for water, oil, fuel, food & beverage, gas, hydrocarbons, drinking water, chemical products, air, steam etc. These seals are manufactured in our own production facility based in Etréchy, in the south of Paris.

The Chromex team is here to advise you on the material best suited to your application and needs, whether it is a red vulcanized fibre (used for sanitary, heating or plumbing applications), an aramid fibre or any other synthetic fibre.

Since many years, Chromex is working with the brand Tesnit®. Therefore, we can offer high quality pressed/compressed fibres with load variations and an elastomer binder that will be vulcanized according to your needs.

The Tesnit® range

Chromex has been manufacturing cut gaskets in synthetic fibres for more than 30 years which are mainly used in the mechanical, chemical, food and water industries. The flat seals of the Tesnit® portfolio covers a wide set of applications and thus to manufacture tailor-made or standard cut gaskets, ranging from prototypes to large series.

Chromex benefits from a wide range of available stock of the most important and commonly used fibre references, such as :

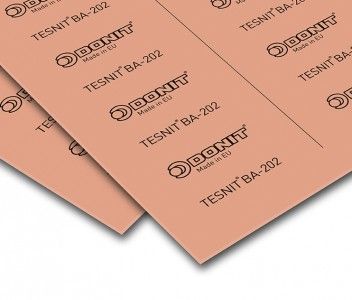

Tesnit® BA-202

Organic fibres with an NBR binder. This material is perfect for gentle applications, for example if in contact with water, oil or food.

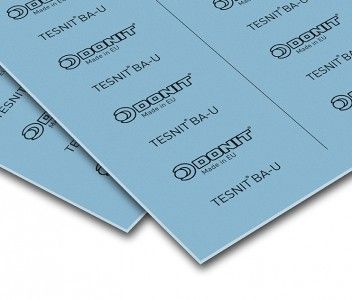

Tesnit® BA-U

Aramid fibres with an NBR binder. This material is the most important standard material of the Tesnit® range. Indeed, the BA-U fibre can be used for many applications, such as drinking water (WRAS and UBA approved) or gas. This material covers a great number of applications thanks to its high thermal resistance (up to 250°C during continuous processes according to use and constraints).

Tesnit® BA-EF

Cellulose fibres with an NR binder. This material benefits from the ACS certification (French Attestation of Sanitary Conformity) for drinking water. This is the only fibre material with this approval.

La Tesnit® BA-GL 3000

Glass fibres with an NBR binder. This material, along with the BA-U, is our second completely standardized material for thicknesses between 0.5 mm and 5 mm. Tesnit® BA-GL 3000 fibre is commonly used for high temperature or gas applications (up to 350°C during continuous processes according to use and constraints).

La tesnit® BA-SOFT

Synthetic fibres with an NBR binder. This is the most recent material of the Tesnit® range which allows to fix different issues: indeed, the BA-Soft is a fibre material with a high coefficient of compressibility, a great elastic recovery and a low gas permeability. This material ensures static sealing for applications where a fibre material with great mechanical properties and high flexibility (close to elastomer flexibility) would be needed. The BA-Soft is perfectly adapted to applications in the pump and compressor industries as well as in the car and the shipbuilding industries.

Les matières de la gamme Tesnit

Moreover, we also provide many other materials from the Tesnit® range at Chromex to produce your tailor-made cut gaskets: carbon fibres or synthetic graphite fibres.

The Chromex team is at your disposal to help you choose the best material that will meet your requirements and needs. We will be able to offer you the best available equivalent material in order to produce your gasket within 48 hours.

Other synthetic fibers

Chromex can produce your specific flat seals (according to your drawings) in different synthetic material brands or in equivalent materials. We handle Garlock® brands and have the possibility to offer you short delivery times for the Blue-Gard® Style 3000 (aramid fibre with an NBR binder) and IFG® 5500 (inorganic fibres with an NBR binder) ranges. For application within the industrial sealing filed, we can provide you with cut gaskets from the Reinz® (AFM® range) and Klinger® brands (Klingersil® range).

Red vulcanized fibre

The red vulcanized fibre is a standard material used for threadings of cold and hot-water pipes. Flat red vulcanized fibre gaskets resist to water and to detergent products.

In some cases, we can provide you with drinking water approved red vulcanized fibre gaskets (ACS approval – French attestation for sanitary conformity). Chromex benefits also from available stock of standard red vulcanized fibre gaskets.

Chromex’s red vulcanized fibre gaskets can be used in valve heads, heating systems or any other plumbing application.